Wagon is a heavy four-wheeled vehicle pulled by draught animals or on occasion by humans, used for transporting goods, commodities, agricultural materials, supplies and sometimes people. The Truck Star company manufactures Wagons.

It involves 7 work stations with different cycles time. Bottleneck on the line balancing production is caused by the difference in cycle time at each work station. This causes a delay in the production of the product. Delays in delivery of goods certainly creates a bad image of the company in the eyes of the customers. Therefore, companies need to balance the line, balancing production to reduce bottlenecks. Minimization in Bottleneck will increase the efficiency of the assembly line.

Introduction

In manufacturing industry production activities are closely related to Assembly line balancing. Assembly line balancing is one of the ways to determine the effectiveness of the industry in which a number of assembly work elements are grouped together into several work stations. Each work station should have the same cycle time though with different capacities so that minimum idle time and bottlenecks occur.

This case is of industries that produce Wagons. It has seven work stations with different capacities. The differences in capacities cause various problems in line balancing. Bottleneck activity causes problem, as it results into a longer cycle time which causes a delay in the completion of the product. Delays in delivery of goods certainly gives a bad name to the company. Hence, it must be handled quickly and one way to handle the line balancing problem is to do the assembly line balancing. Line balancing is a method to balance the assignment of some work elements from an assembly line balancing to the work station to minimize the number of workstations and minimize total of idle time on the whole work station on a certain level of output. Therefore, it is necessary to do the line balancing to this company which aims to reduce the bottleneck to increase line efficiency and reduce balance delay.

Line Balancing is levelling the workload across all activities to remove bottlenecks and excessive capacity. The main objective of line balancing is to distribute the task evenly over the work station so that idle time to man of machine can be minimized and to minimize total of idle time on the whole work station on a certain level of output. In general, the main purpose of line balancing is how to minimize the number of work stations and to improve the production rate. In addition, line balancing is also used to obtain the minimization of cycle time; the maximization of workload smoothness; and the maximization of work relatedness. There are some indicators used to determine the quality of line balancing, line efficiency, smoothing index and time of line balancing

Assembly Line Balancing is a heuristic method and is one of the most popular techniques for solving the problem. This method has also been widely used in a variety of manufacturing industries including in the t-shirt industry consisting of 15 work elements. Heuristic approaches have also been done on CNC machines. However, no research has been done to reduce balance delay and increase line efficiency in industries that produce transportation equipment such as dump trucks.

Method

The ALB problem is one of assigning all tasks to a series of workstations so that each workstation has no more than can be done in the workstation cycle time, so that the unassigned (i.e. idle) time across all workstations is minimized. Total work to be performed at a work station is equal to the sum of the tasks assigned to that work station. Work station cycle time is the time between successive units coming off the end of the line.

Steps in Assembly Line Balancing:

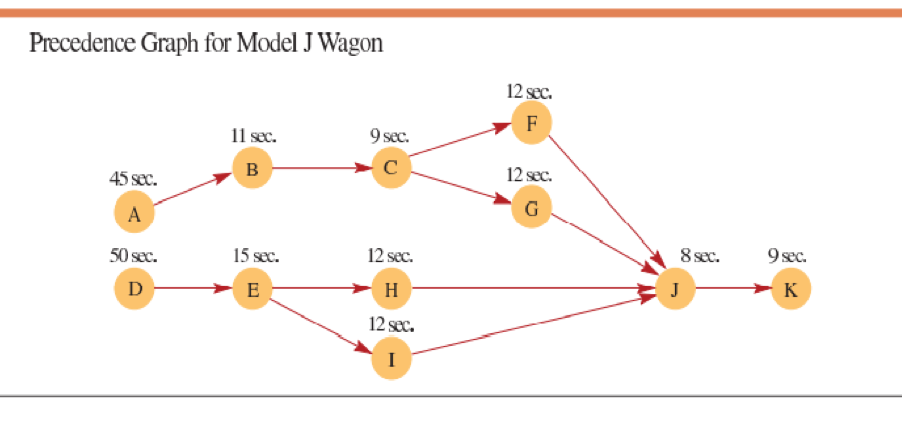

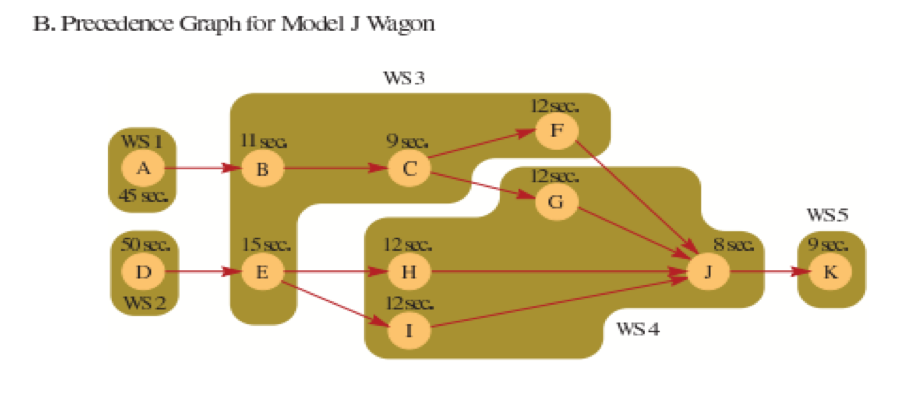

- Specify the sequential relationships among tasks using precedence diagram consisting of circles (individual tasks) and arrows (order of task performed).

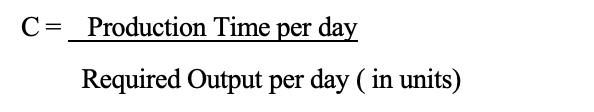

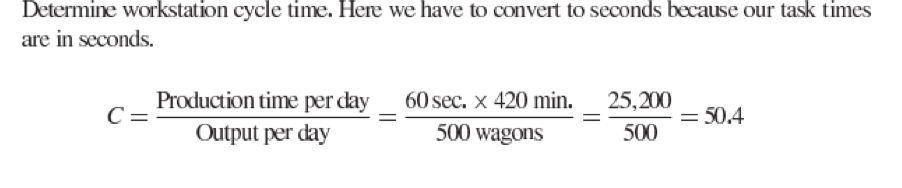

- Determine the required workstation cycle time C:

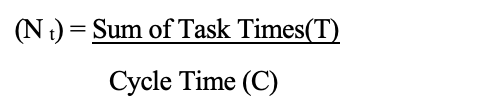

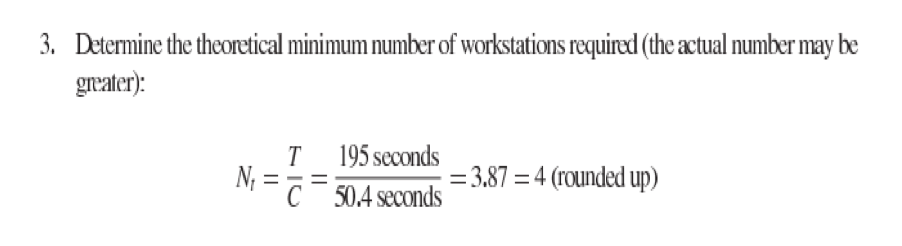

3. Determine the theoretical minimum number of workstations

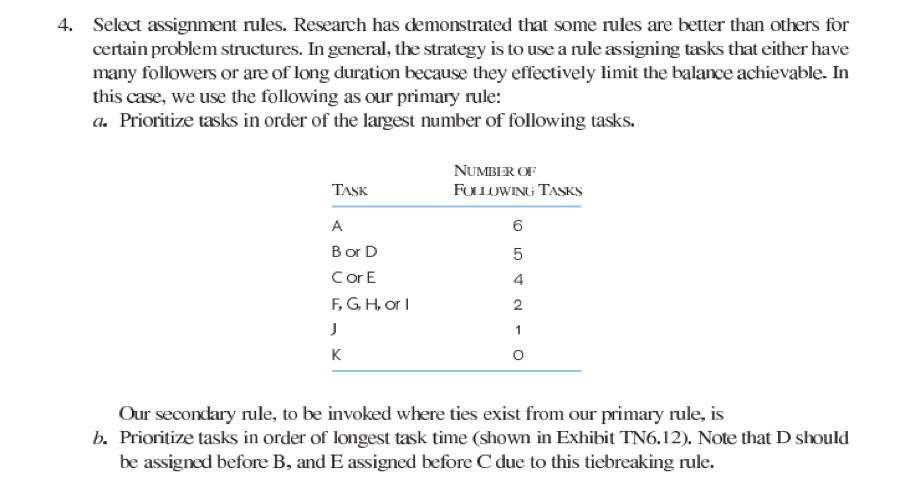

4. Select a primary rule by which tasks are to be assigned to workstations and secondary rule to break ties.

5. Assign tasks one at a time to the workstation until the sum of the task times is equal to the work station cycle time, or no other tasks are feasible because of time or sequence restrictions. Repeat the process for WS 2 & 3 until all tasks are assigned.

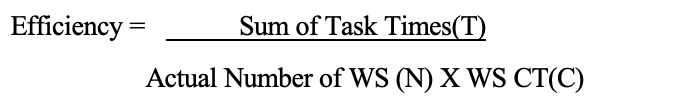

6. Evaluate the efficiency of the balance derived using:

7. If efficiency is unsatisfactory, rebalance using a different decision rule.

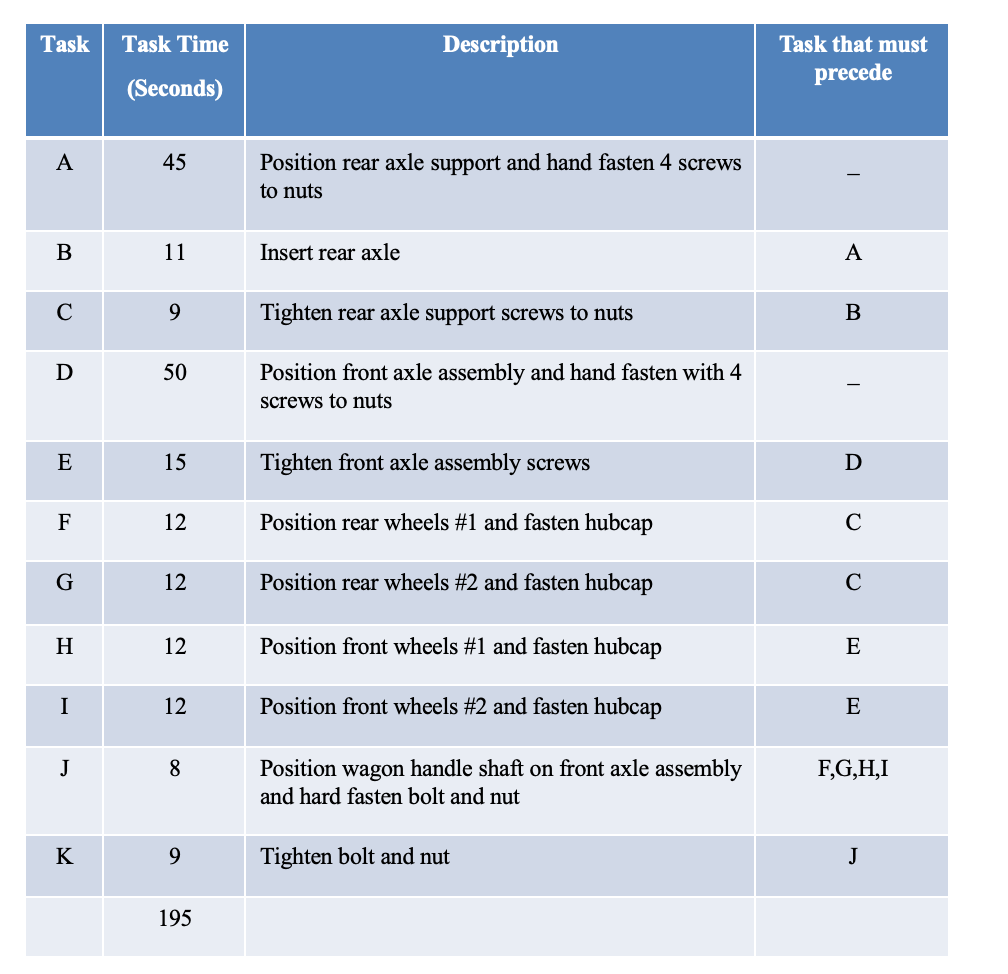

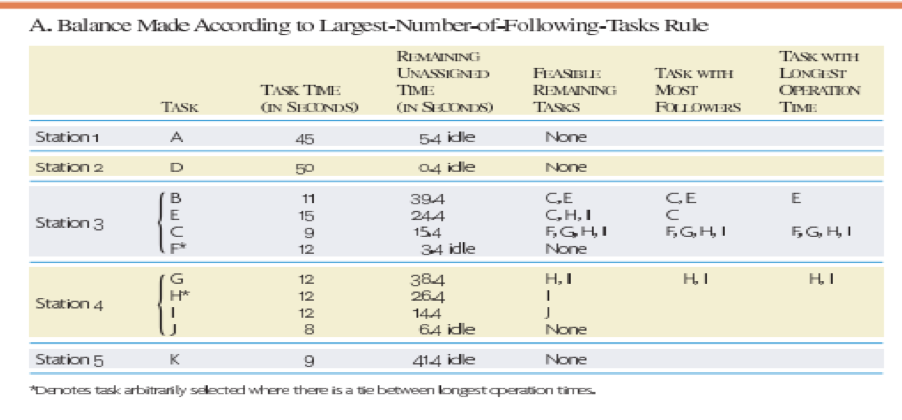

The Star Truck Company needs to assemble dump trucks on a conveyor belt. 500 Dump trucks are required per day. Production time per day is 420 minutes and the assembly steps and times for the dump trucks have been shared by the company. In order to find the balance that minimizes the number of work stations, subject to cycle time and precedence constraints Assembly Line Balancing was used.

STEP 1: Precedence Diagram

STEP 2:

STEP 3:

STEP 4:

STEP 5:

Efficiency Calculation

Evaluation:

- An efficiency of 77% indicates an imbalance or idle time of 23% across the entire line.

- There are 57seconds of idle time!

Efficiency can be further improved trying with rule B and breaking ties with rule A

JIMS, Kalkaji

#jims #jimsdelhi #managementcollegeindelhi #pgdmcollegesindelhi #mbacollegesindelhi #toppgdmCollegesindelhi #topbschoolsindelhi ##manufacturing Industry #Assembly line Balancing #Efficiency #Production #Bottleneck

For more information visit: www.jagannath.org/